When it comes to the mechanics of boats, many people wonder if boats have transmissions similar to cars. While the concept of transmissions is common in land vehicles, the marine world operates on a different set of principles. In this comprehensive article, we will delve into the topic of boat transmissions, exploring how marine propulsion systems work to provide a detailed understanding of the subject.

How Do Boats Move Without Transmissions?

Contrary to cars that rely on gear shifting to transfer power from the engine to the wheels, boats operate on a different principle altogether. Instead of a transmission, boats use different types of propulsion systems to generate thrust and propel through the water. These systems work in conjunction with the boat’s engine and other components to ensure smooth and efficient movement.

The Basics of Marine Propulsion Systems:

To understand how boats move without transmissions, it is crucial to grasp the basics of marine propulsion systems. The primary purpose of a boat’s propulsion system is to convert the engine’s power into forward motion. This is achieved by harnessing the force generated by the engine and efficiently transferring it to the water, propelling the boat forward.

The main components of a marine propulsion system include the engine, propeller, and the system responsible for transferring power to the propeller. Instead of relying on gears to transmit power, boats use the rotation of the propeller, which acts as a type of “built-in” transmission mechanism.

Types of Boat Propulsion Systems:

There are various types of boat propulsion systems, each with its unique characteristics and advantages. Here are three common types:

3.1. Inboard Engines:

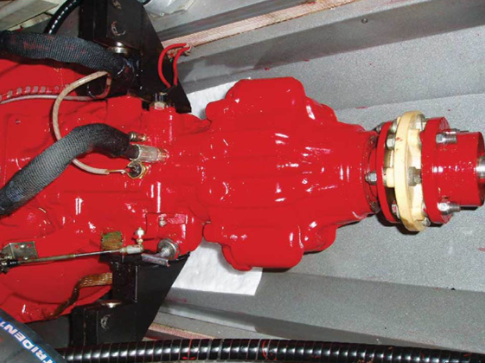

Inboard engines are typically located inside the boat’s hull, near the center. These engines generate power and transfer it to the propeller through a driveshaft. Inboard engines are commonly used in larger boats and are known for their efficiency, power, and smooth operation.

Inboard engines can be further classified into direct drive and V-drive systems. Direct drive systems have the engine aligned directly with the propeller shaft, while V-drive systems use a transmission-like component to redirect the engine’s power at a specific angle before reaching the propeller.

3.2. Outboard Motors:

Outboard motors are self-contained units mounted on the transom at the rear of the boat. They consist of an engine, gearbox, and propeller. The entire unit can pivot, allowing for steering and adjusting the thrust direction. Outboard motors are versatile, easy to maintain, and are commonly found on smaller boats.

Outboard motors incorporate a gear system within the gearbox to adjust the power output and control the propeller rotation speed. This gear system allows for forward, neutral, and reverse gears, providing greater control over the boat’s movement.

3.3. Stern Drives:

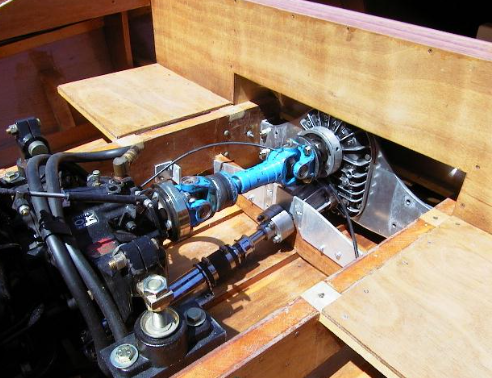

Stern drives, also known as inboard/outboard (I/O) drives, combine the features of inboard engines and outboard motors. They are installed inboard, but the engine is connected to the drive unit mounted externally on the transom. This configuration provides better maneuverability, as the drive unit can be tilted and turned. Stern drives are popular on recreational boats due to their flexibility and performance.

Stern drives employ a combination of gears and a universal joint to transfer power from the engine to the propeller. The gears allow for different ratios, enabling the boat to achieve optimal performance across a range of speeds.

Understanding the Role of Marine Gears:

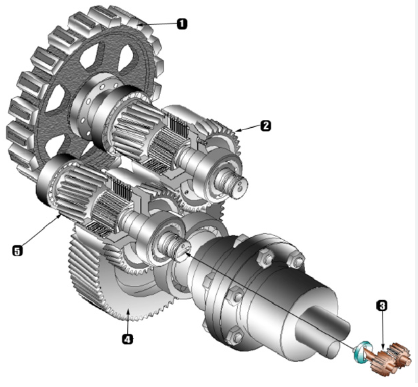

Although boats do not have traditional transmissions, they often incorporate marine gears to optimize performance and control. Marine gears play a crucial role in the propulsion system, providing the ability to adjust the speed and torque of the propeller, ensuring efficient power delivery.

4.1. Gear Ratios and Performance:

Marine gears use different gear ratios to convert the engine’s high-speed rotation into a suitable speed for the propeller. By altering the gear ratio, boats can adapt to various conditions, such as cruising at high speeds or maneuvering in tight spaces. Different gear ratios are achieved by changing the size and number of gear teeth within the gear system.

4.2. Controlling Speed and Torque:

The ability to control speed and torque is essential for boat propulsion systems. Marine gears allow operators to select the optimal gear ratio based on the boat’s requirements. Lower gear ratios offer increased torque for better acceleration, while higher gear ratios provide higher speed capabilities. Having control over speed and torque allows boaters to navigate various water conditions and optimize fuel efficiency.

Essential Maintenance Tips for Boat Propulsion Systems:

To ensure the longevity and reliability of your boat’s propulsion system, regular maintenance is crucial. Here are some essential maintenance tips:

5.1. Regular Inspection and Cleaning:

Inspect the entire propulsion system, including the engine, propeller, and associated components, for any signs of damage or wear. Clean the propeller regularly to remove any debris that could affect performance. Inspecting the propeller for dents, cracks, or signs of corrosion is particularly important, as it directly affects the efficiency and thrust generated.

5.2. Oil and Lubricant Checks:

Check the oil levels in the engine and gearbox regularly, and change them according to the manufacturer’s recommendations. Proper lubrication of all moving parts is crucial to minimize friction and maximize efficiency. Pay close attention to the propeller shaft, as it requires adequate lubrication to rotate smoothly.

5.3. Propeller Maintenance:

Inspect the propeller for any dents, cracks, or signs of corrosion. Repair or replace damaged propellers promptly to maintain optimal performance. Properly balanced and well-maintained propellers contribute to smooth operation and fuel efficiency. Additionally, ensure that the propeller blades are properly aligned and balanced to minimize vibrations and increase overall efficiency.

The Future of Boat Propulsion: Electric and Hybrid Systems:

As environmental concerns continue to grow, the marine industry is exploring alternative propulsion systems. Electric and hybrid systems are gaining traction, offering quieter operation, reduced emissions, and improved fuel efficiency. These systems utilize electric motors and batteries to power the boat, and in some cases, they can be combined with traditional propulsion systems for added versatility.

6.1. Electric Propulsion Systems:

Electric propulsion systems use electric motors powered by batteries or other onboard power sources. They offer smooth and quiet operation, zero emissions, and low maintenance requirements. Electric systems are particularly suitable for smaller boats and can provide sufficient power for recreational cruising.

6.2. Hybrid Propulsion Systems:

Hybrid propulsion systems combine traditional internal combustion engines with electric motors and batteries. These systems offer the flexibility of both power sources, allowing the boat to operate in electric-only mode for short distances or at lower speeds, and switch to the internal combustion engine for longer trips or higher speeds. Hybrid systems provide increased efficiency and reduced environmental impact compared to conventional propulsion systems.

Conclusion:

While boats do not have traditional transmissions like cars, they utilize various propulsion systems to transfer power to the propeller and generate forward motion. Understanding the basics of marine propulsion systems, including inboard engines, outboard motors, and stern drives, provides a foundation for boat owners to maintain their propulsion systems effectively.

Regular maintenance, such as inspection, cleaning, and propeller maintenance, ensures optimal performance and extends the lifespan of these critical components. As the industry continues to evolve, electric and hybrid propulsion systems represent a promising future for boating, offering environmentally friendly alternatives without compromising performance.